A guide to Perspex and Polycarbonate cutting and fabrication techniques

Published on: 16/07/2024

Why might a potential customer need the services of a team with exceptional experience in CNC plastic fabrication and other techniques? Typically it's because they require a custom shape cut to size with detail such as intricate or irregular shapes or accurately positioned and drilled holes, all of which are very hard to acheive without modern CNC machinery. At Simply Plastics, our team have the know-how that comes from more than 30 years' experience working with plastic products. But what's the difference between our CNC routing service and our laser cutting service? When would you need diamond polishing, or line bending? In this article we explore the different cutting and fabrication services that we offer.

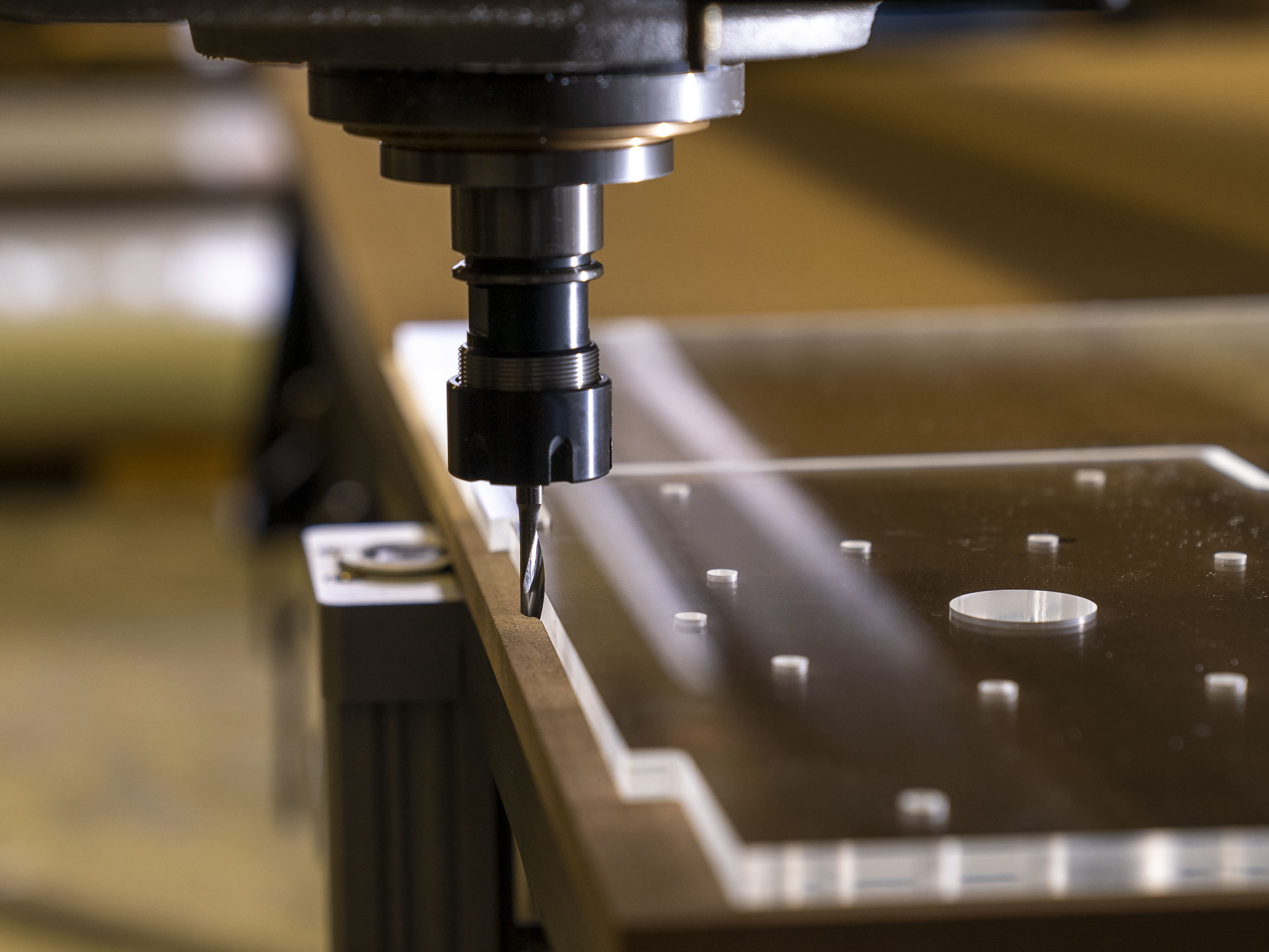

CNC Routing

Accuracy, versatility and repeatability are just three of the reasons why you might choose to use our CNC routing services. A CNC (computer numerical control) router cuts shapes by moving a high-speed rotary cutter to specific X (left and right), Y (back and forth) and Z (up and down) coordinates throughout the machine's available working area. Our plant includes two state-of-the-art Multicam Apex 3R (3 axis) routers which enables us to meet extremely tight tolerances and precision time after time.

Our CNC routing services are popular because they embrace an extensive range of options including shaping, profiling and cutting. The versatility of this technique means it can be used on a variety of materials including Perspex, Polycarbonate, and even composites such as Aluminium Composite Panel. This is one of the major advantages of CNC routing versus CNC Laser cutting, which for the most part is limited to cutting Perspex and other non-toxic plastics.

Whether you need a one-off, a short run or a large-scale production, the combination of our state-of-the-art machinery and our dedicated and experienced in-house team ensures your project will be delivered on time and on budget.

Some of the many applications of CNC routing are:

- Signage

- TV/film/theatre set design

- Glazing

- Machine guards

- Components for machinery

CNC Laser Cutting

When you want a powerful and precise cut, our laser cutting service can deliver it. This process uses a laser beam to cut through the surface of a wide range of materials. Our plant includes the following:

- Lotus Blu125 CO2 laser, 200w power rating

- Lotus Blu125 CO2 laser, 100w power rating

- Trotec Speedy 300, 80w power rating

- Trotec Speedy 100R, 50w power rating

Our CNC Lasers work by focusing light through mirrors and lenses to deliver an intense beam with the power to cut complex shapes quickly, and with a high level of precision.

CNC Laser cutting is well suited to delivering small parts from easy to cut plastics such as Perspex.

Applications of our laser cutting services include:

- Custom shapes

- Components for machinery

- Prototypes

- Point of sale items

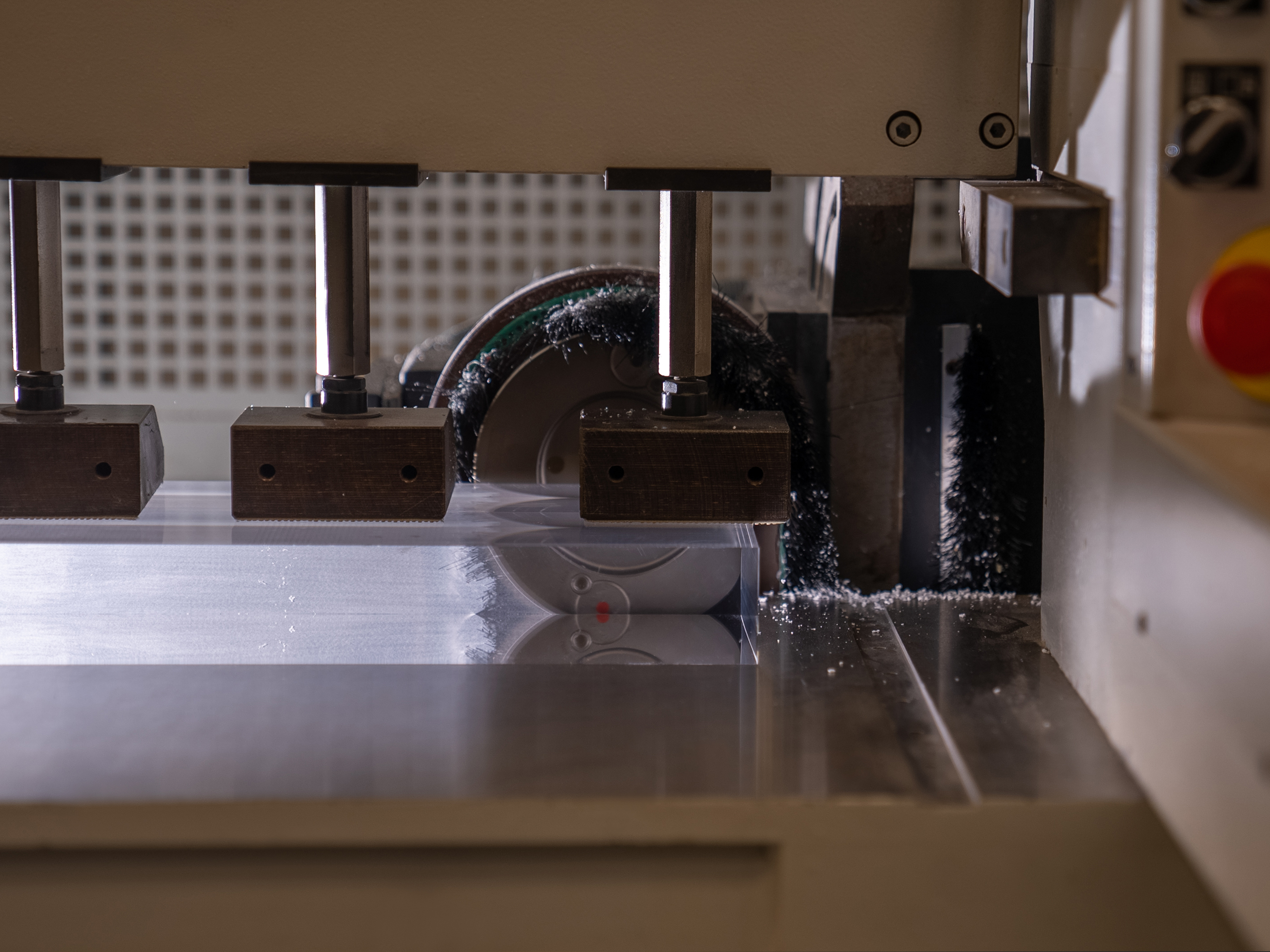

Diamond & Flame Polishing

As you might guess from the name, this is a CNC plastic fabrication method that complements a cutting process and delivers a perfect finish.

Once a Perspex part or panel has been cut using either a saw or cnc router there may be visible tool markings on the edges of your plastic sheet. Our diamond and flame polishing service take away any cut marks and produce a smooth edge.

Our technicians use Bermaq Am-1 and Am-2 diamond polishers, which apply a diamond-tipped polishing wheel to the edge of your material. These polishers can treat several panels at once, which means a fast turnaround time.

However, diamond polishers can work only on straight edges. If you have a curved cut, you need a flame polisher which temporarily melts the surface to enable the creation of a clean, smart finish.

Frequent uses of diamond and flame polishing include:

- Retail display

- Signage

- Awards

Laser Engraving

Laser engraving is the answer when you want to permenantly mark text and/or shapes into the surface of a material.

Our laser engraving is carried out using state-of-the-art Trotec lasers, which can cut and engrave fine detail in a broad range of engravable surfaces. As well as plastic, we can work with glass, stone, wood, leather and even some metals.

The laser creates a finely targeted beam whose heat melts or vaporises the surface to create designs or to write letters that carry an important message that lasts for years. People come to us with a host of reasons why they need such engravings.

Among the typical uses of laser engraving are:

- Memorial plaques

- Trophies and medals

- Electrical warning labels

- Machinery labels

- Control panels

Line Bending

There may be circumstances in which you need to create precise folds in tough pieces of plastic. This is when you need a line bending service that delivers the finished effect you seek.

Whether you require a straightforward fold in a thin material, or several bends in strong plastics up to an inch thick, the strip heaters and jigs that we use will do the trick.

Line benders heat the plastic is specific places until it is soft enough to be manipulated into the desired shape. When it cools down, that new shape remains.

Popular applications for line bending are:

- Furniture

- Brochure holders

- Retail display

- Literature display

- Point of sale items

Why work with Simply Plastics?

When you work with us, you have the reassurance of knowing you are working with a dedicated, expert team that uses state-of-the-art machining technology. We are a trusted leader in our industry, leveraging more than 30 years’ experience in CNC plastic fabrication to transform your ideas into superlative reality.

As well as being home to the last word in plastic machining, we also stock a market-leading range of plastic sheets, tubes, discs and rods. This gives us easy access to materials such as Perspex®, Dibond, Foamex, Polycarbonate, PVC and Acrylic mirror.

Frequently asked questions

Yes we can. Customised, cut-to-size materials can be ordered directly through the website, but if you require further fabrication we can help you with this too.

Our fabrication services include,

- CNC routing

- Bending

- Shaping

- Bonding/gluing

- Diamond polishing

- Flame polishing

- Intricate laser cutting

Examples of fabricated products include,

- Acrylic display cases

- Point of sale

- Retail display

- Lighting applications

- Brochure holders

- 2D/3D Acrylic lettering

- Furniture

- Office Interiors

For enquiries regarding any project from prototypes to large production runs, please get in touch to discuss your requirements.

The answer to this question is not clear cut. Aluminium Composite Panel (ACP) is a composite of two main materials, the outer skin which on most ACP is 0.3mm Aluminium and the inner core with is made from Low Density Polyethelyne (LDPE). This means that we have to consider how both of these materials react to laser cutting.

Aluminium can be laser cut however a high powered laser is required - typically 500+ watts is required to produce a clean cut on 3mm aluminium. On the other hand, Polyethelyne can be laser cut at a relatively low power, in-fact if Polyethelyne is laser cut with a high powered beam it does tend to warp and/or melt.

Therefore the power and temperature required to laser cut through the two primary materials in ACM are very different and this unfortunately makes laser cutting ACM virtually impossible. The power and heat required to laser cut aluminium will be so high that it will likely warp, melt or blow holes through the polyethelyne. Contrastly, if the laser is set to the low power levels required to laser cut polyethelyne it won't be anywhere near powerful enough to even mark the aluminium, let alone cut through it.

Both PETg and Polycarbonate are thermoplastics that share some similarities with Perspex®, certainly there are many applications where any of the three materials could be used. Polycarbonate doesn’t react well to flame polishing because the surface being heated tends to bubble and distort whereas PETg reacts remarkably well to the heat from flame polishing and it is possible to achieve similar results to that of Perspex®. Diamond polishing is also possible with both PETg and Polycarbonate provided the right type of cutters are used.

{{product.colours}} Colours

{{product.colours}} Colours