A guide to Twinwall and Multiwall Polycarbonate

Published on: 01/03/2024

The plastic sheeting industry has grown tremendously over recent decades as demand has increased for materials and products suitable for use in construction, retail, engineering, and DIY projects. Polycarbonate is a particularly popular product that is available in multiple forms including flat sheet, corrugated, and multiwall. In this article, we’re going to be delving deeper into Twinwall and Multiwall Polycarbonate.

What is Polycarbonate?

Polycarbonates are a group of thermoplastic polymers which, in contrast to single-use plastics, are 100% recyclable. Polycarbonate is an incredibly versatile product, it’s extremely strong and tough yet can be easily worked, molded and thermoformed. Additionally, polycarbonate has extremely high impact-resistance (although low scratch-resistance) and will hold up to extreme temperatures – typically polycarbonate will soften at temperatures in excess of 150 °C (302 °F) which means it can undergo large plastic deformations without cracking or breaking which makes it perfect for applications in construction and outdoors. Simply Plastics supply polycarbonate in a number of different forms including Clear (which is very popular for replacing glazing in sheds, greenhouses and skylights, and as secondary glazing.), Opal, Prismatic, Clear Georgian Wire, Obscure Georgian Wire and Twinwall/Multiwall which is used in roofing applications.

What is twinwall and multiwall polycarbonate?

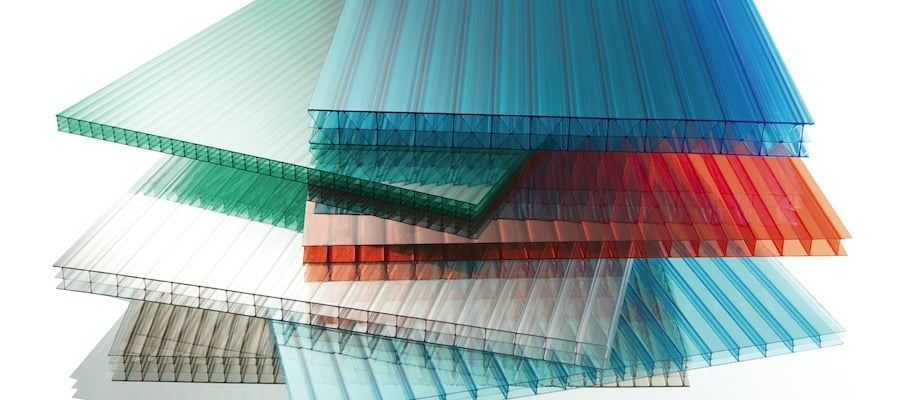

Twinwall and multiwall polycarbonate is a high-quality, versatile glazing product that can be used as an alternative to glass in many applications ranging from greenhouse glazing to roofing and conservatories including agricultural applications such as cow sheds and barns. It comes in the form of hollow lightweight flat sheets of various thickness, size, structure and tint/colour.

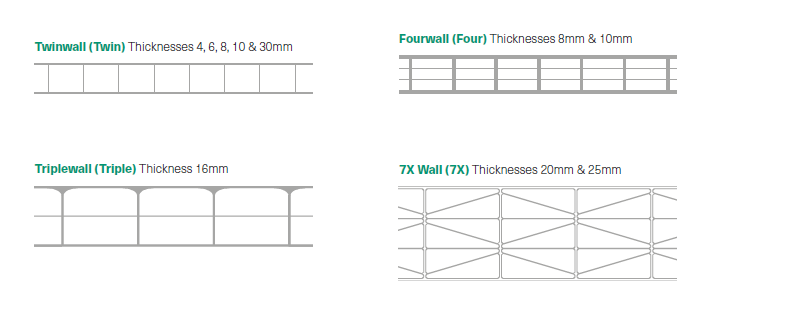

Unlike solid polycarbonate sheet, Twinwall and Multiwall Polycarbonate sheet is constructed using multiple layers of plastic, forming a honeycomb-like structure, some examples of which are shown below:

Typically twinwall refers to the variant that has just two walls whereas multiwall is the term used generically to refer to any variant with three walls or more.

The structure and properties of multiwall polycarbonate make it the ideal choice for vertical applications such as greenhouse glazing, and horizontal applications such as roofing and lean-to’s, for a number of reasons:

- 200 times stronger than glass at only a fraction of the weight

- Excellent impact resistance

- Rigid and self-supporting allowing architectural spanning applications

- Suitable for use in temperatures ranging from -40 C to 100 C making it a great glazing solution

- Co-extruded UV protection layer filters out over 98% of UV rays for enhanced weatherability, preventing yellowing and loss of strength

- The multiwall structure provides a thermally insulating glazing solution

In-regards to thermal insulation, the more layers a twinwall/multiwall polycarbonate sheet has, the more insulation it provides. If the project requires heat containment, then Multiwall will be a better choice than Twinwall as it provides more insulation.

Twinwall and Multiwall polycarbonate is an incredibly versatile product, here’s a recap of its properties and why you’d choose it:

- It’s lightweight yet durable

- It’s UV and highly impact-resistant

- It’s thermally efficient

- It’s easy to install

- It allows up to 82% light transmission

- It’s easy to clean

Common Uses

Twinwall and Multiwall Polycarbonate has an extensive range of uses and is often fitted on roofing and glazing projects where it is a popular alternative to glass. It’s a relatively inexpensive product which gives great results compared with traditional wooden or metal roofs because it lets natural light flood in.

Common uses include:

- Lean-to extensions and orangeries

- Carports

- Canopies

- Pergolas

- Patio covers

- Conservatories

- Sunrooms

- Greenhouse glazing

- Secondary glazing

- Shed glazing

- Windbreaks

- Cold-frames and cloches

- Skylights

Other Uses

Multiwall and twinwall polycarbonate is also commonly used in the manufacture of signage and display materials, as well as for screening applications in residential and workplace environments (see image below).

Twinwall and Multiwall Options

At Simply Plastics all of our Marlon ST Twinwall and Multiwall Polycarbonate benefits from exceptional optical clarity, light transmission, impact resistance and durability. We provide all of our Twinwall and Multiwall sheeting Cut to Size, with no extra charge, and with multiple depth options:

Cutting Multiwall Polycarbonate Sheets

Twinwall and Multiwall Polycarbonate sheets are very easy to cut to size. You just need a fine-tooth saw. The saw doesn’t need to be powered, as cutting the sheets by hand will enable a cleaner and more accurate cut.

A great benefit of choosing Simply Plastics as your online Polycarbonate supplier is that all you need do is select the size of your Twinwall or Multiwall sheet, and we’ll do the rest.

Our free Cut to Size service enables you to purchase a wide range of plastics including Perspex, Polycarbonate and Aluminium Composite Sheet, at the exact dimensions you require, without having to purchase the manufactured sheet size, normally 3m x 2m. Saving you time, money and reducing wastage.

The Marlon ST Polycarbonate Roofing System

At Simply Plastics we stock and supply the Marlon ST Polycarbonate Roofing System, previously branded as Corotherm, which is manufactured in the UK by Brett Martin. The range includes all of the components required to install a fully weatherproof and waterproof roof and it used by both professional fitters and DIY'ers alike.

Polycarbonate Roofing Sheet

Twinwall and Multiwall Polycarbonate sheet available in Clear, Opal and Bronze finishes in standard sheet sizes or cut to size.

Glazing Bar

Roofing Glazing Bars are fitted to rafters to support and join roofing sheets.

End Cap

Glazing Bar End Caps are fitted to the ends of glazing bars for a neat finish.

Side Flashing

Glazing Side Flashing is used to finish the side edges of the polycarbonate roofing sheet.

End Closure

The Roofing End Closure finishes the front edge of the roofing sheets.

Butyl Flashing

Butyl Wall Flashing Tape is applied where the roofing sheet meets the wall to prevent water entering the joint between the two surfaces.

Solid Tape

Solid Roofing Tape is used to cover and seal the open flutes at the end of the roofing sheets, it's specifically used to seal the end of the roofing sheet that meets the wall.

Breather Tape

Roofing Breather Tape is applied to the open edge of the bottom side of the roofing sheets. It creates a protective seal while permitting air to move freely in and out of the sheet, helping minimise condensation.

Related FAQs

Simply Plastics offer Marlon ST Polycarbonate multiwall sheet in thickness of 10mm, 16mm and 25mm to suit different applications.

Here are some example applications to guide your decision,

10mm - Garden Pergola, Vertica privacy glazing

16mm - Gazebos, Lean-tos, Carports

25mm - Large lean-to extensions, Garden buildings

We offer multiwall sheet in three finishes, Clear, Opal and Bronze. Each finish offers different benefits to suit different requirements.

Clear - High light transmission with most standard appearance

Opal - Lower light transmission provides increased privacy and heat reduction

Bronze - Reduces glare

Clean with a mild solution of water and washing detergent using a soft microfibre cloth.

With proper care, twinwall/multiwall polycarbonate sheets should last in excess of 10 years. The polycarbonate we supply is guaranteed against discoloration for 10 years.

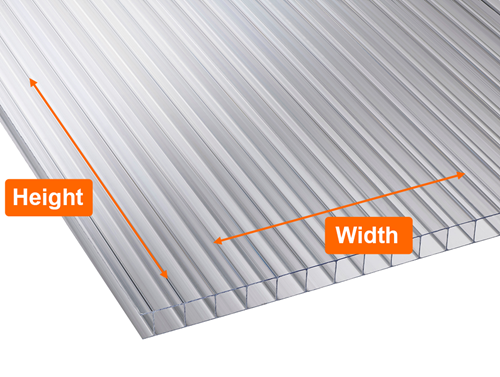

The flutes run parallel to the height of a sheet.

{{product.colours}} Colours

{{product.colours}} Colours