Etched Polycarbonate - the modern alternative to Georgian Wire Glass

Published on: 01/09/2022

Quite a lot of what we take for granted today has its origins in the Georgian period. Did you know, for example, that everything from landscaped gardens to coffee shops to celebrity culture harks back to the reigns of Georges I to IV? The Georgian era in general was a time of immense social change – and also the age that saw Britain establish itself as an international power at the heart of an expanding empire. This period is also well known as the start of a golden era in art, architecture and interior design. Which brings us rather neatly onto the subject of Georgian Wire Glass.

What is Georgian Wire Glass?

Georgian Wire Glass (sometimes referred to – though not especially accurately – as safety glass) was patented by Frank Schuman in 1892. As its name suggests, this material is basically glass that is embedded with wire mesh during the manufacturing process. This wire is usually available in either square or diamond grids.

While this wire mesh doesn’t actually improve the impact resistance of the glass, it helps to minimise shattering, by retaining any broken pieces and maintaining its structural identity. This has both advantages and disadvantages. From a security point of view, Georgian Wire Glass can help to prevent break-ins and burglaries. However, impact can leave jagged shards and sharp wires in the glass exposed, which has obvious safety/injury concerns, especially in high-traffic areas.

The other main benefit of Georgian Wire Glass is that it can be used as a relatively low-cost fire-resistant option. It also has a higher resistance to thermal and electric shock in comparison with ordinary float glass.

Georgian Wire Polycarbonate: the modern alternative

Happily, technology has moved on significantly since Georgian times, and nowadays there is a much better alternative to Georgian Wire Glass. Georgian Wire Polycarbonate mimics its appearance, but is a lighter, safer, cheaper option that is ideal for a wide variety of environments, from train stations to hospitals to period buildings to prisons.

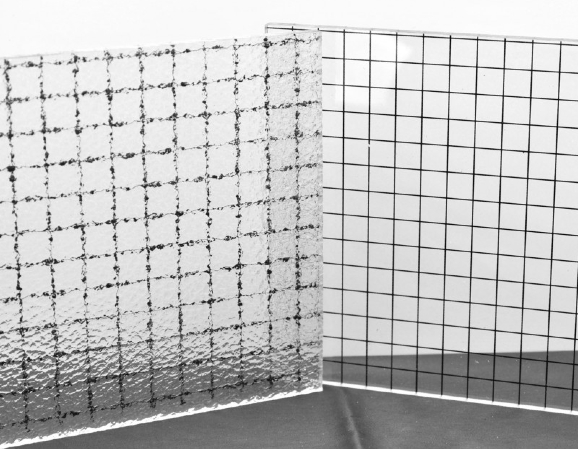

We offer two different types of Georgian Wire Polycarbonate: clear and obscure. The latter provides a greater level of privacy, while still transmitting high levels of light. Both types are manufactured using advanced technology that etches a wire effect onto the surface of a polycarbonate sheet. This process retains that all-important traditional Georgian wire aesthetic and heritage – without the well-documented safety issues of combining actual wire and glass.

The general pros of Polycarbonate

Polycarbonate is a tough, transparent, practical plastic that offers excellent impact resistance. Well known for its durability and damage-resistance, polycarbonate is almost unbreakable, making it the optimum glazing choice wherever safety and security are paramount.

Another bonus? Its durability translates into longevity. Georgian Wire Polycarbonate is far less likely to need replacing or repairing than its traditional glass counterpart, making it an even more cost-effective selection.

Despite its strength and sustainability, polycarbonate is lightweight. This not only makes it easy to install, it also prevents damage during shipping, minimises transportation costs, and reduces loadings on glazing structures and framework. Here’s a helpful comparison. A 1m diameter circle of 6mm Georgian Wire Glass would weigh around 11.78kg. However, a 1m diameter circle of 6mm Georgian Wire Polycarbonate would weigh just 5.69kg – a huge difference.

Key features and typical applications

Both our clear and obscure Georgian Wire Polycarbonate sheets are 6mm thick. They are available in a range of different lengths and widths, and can be pre-cut to your exact measurements – ready to be fitted – with or without pre-drilled holes. The maximum sheet size is 2440mm x 1220mm.

Virtually indistinguishable in appearance from traditional Georgian Wire Glass, our Georgian Wire Polycarbonate is ideal for heritage and listed building glazing. With around 250 times the impact of glass, it complies with Safety Glazing EN12600:2002, Balcony Glazing EN12600:2002 and Security Glazing EN 356:2000 regulations. Importantly, as there is no actual wire to rust, our Georgian Wire Polycarbonate is also weather-resistant, and is offered with a ten-year limited warranty against UV discoloration and loss of impact.

Furthermore, this versatile material incorporates excellent temperature stability. There is no loss of property from -40˚C to 130˚C, making it secure for most geographic locations and applications. Georgian Wire Polycarbonate also has a Class 1 fire rating – the highest of British Standard 476 (part 7) fire resistance classifications.

Unlike single-use plastics which contribute significantly to plastic waste, our carefully curated portfolio incorporates both recycled and recyclable plastics, to help create a safer and more sustainable environment. Our Georgian Wire Polycarbonate sheets are straightforward to fully recycle, unlike Georgian Wire Glass which would need an initial separation process to remove the wire grid from the glass.

Tremendously versatile, our Georgian Wire Polycarbonate portfolio is ideally suited to a huge range of diverse applications and installations including:

- Roofs and skylights

- Fire escape routes/emergency exits

- Schools

- Hotels

- Stairwells

- Hospitals

- Transport hubs

- Prisons

- Period buildings

- Factories

- Swimming pools

- Retail architecture

Keen to find out more about our Georgian Wire Polycarbonate? Please contact us.

{{product.colours}} Colours

{{product.colours}} Colours