Why Engineers Rely on Nylon 6 for High-Load, High-Wear Applications

Published on: 11/09/2025

When strength, durability, and performance matter most, Nylon 6 consistently delivers. As one of the most widely used engineering plastics, it offers a powerful combination of mechanical strength, wear resistance, and cost-effectiveness making it one of the preferred material for demanding, high-load and high-wear environments.

At Simply Plastics, we offer a full range of Nylon 6 sheets and rods, including extruded, cast, and oil-filled grades (LFX Oilon) to suit a variety of engineering applications.

What is Nylon 6?

Nylon 6, also known as polycaprolactam or PA6, is a high-performance engineering plastic and synthetic fibre belonging to the polyamide family. It is a semi-crystalline polymer known for its exceptional strength, wear resistance, and ability to perform under mechanical stress.

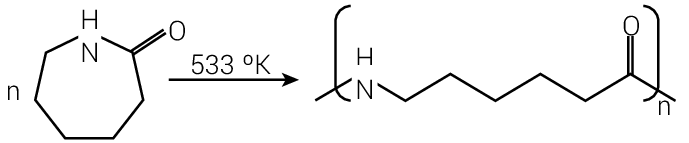

Unlike most nylons, which are made through condensation polymerisation, Nylon 6 is produced through the ring-opening polymerisation of caprolactam, a monomer with six carbon atoms — hence the name ‘Nylon 6’.

Nylon 6 includes 3 variants, Extruded Nylon 6 (PA6E), Cast Nylon 6 (PA6C) and Nylon 6 LFX (also Cast), each having their own pros and cons.

Common Applications of Nylon 6

Nylon 6’s unique combination of strength, wear resistance, and low friction makes it a versatile material used in many industries. Here are some of the most common ways it’s applied:

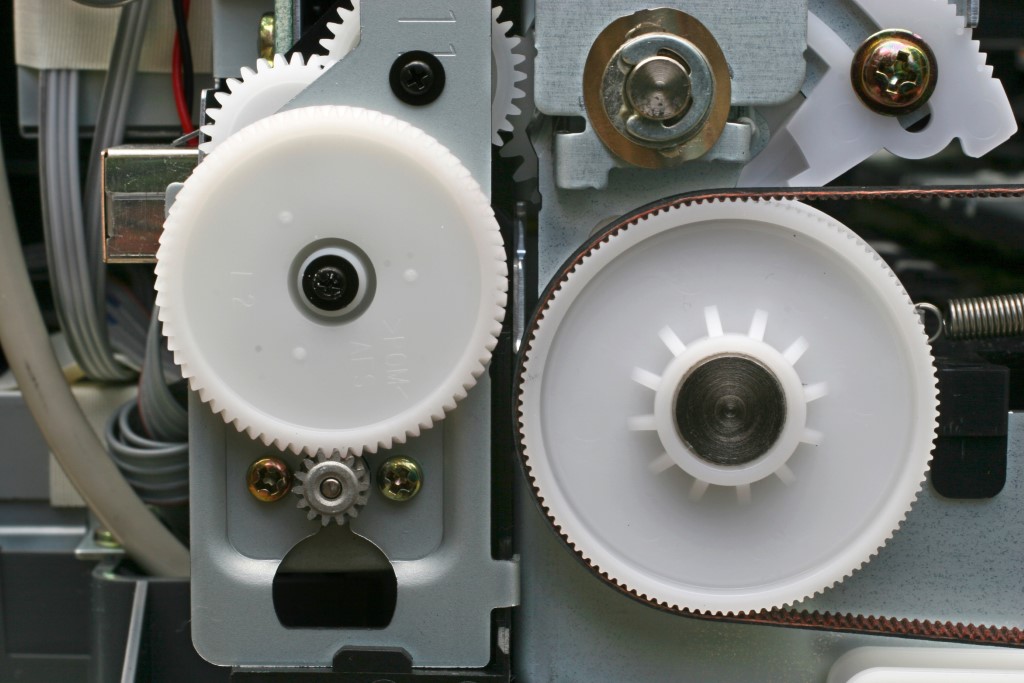

Industrial Machinery and Automation – Nylon 6 is valued for its durability and low friction compared to metals, helping to reduce wear and noise in mechanical systems. While standard Nylon 6 requires external lubrication in many applications, oil-filled grades like Nylon 6 LFX provide built-in lubrication for maintenance-free performance. Examples:

- Gears and sprockets in conveyor systems.

- Wear pads or guide rails for protecting metal components.

Automotive and Transportation – Lightweight and resistant to oils and greases, Nylon 6 helps improve vehicle efficiency and reduce noise. Examples:

- Timing gears and chain tensioners.

- Cable guides or pulleys under the hood.

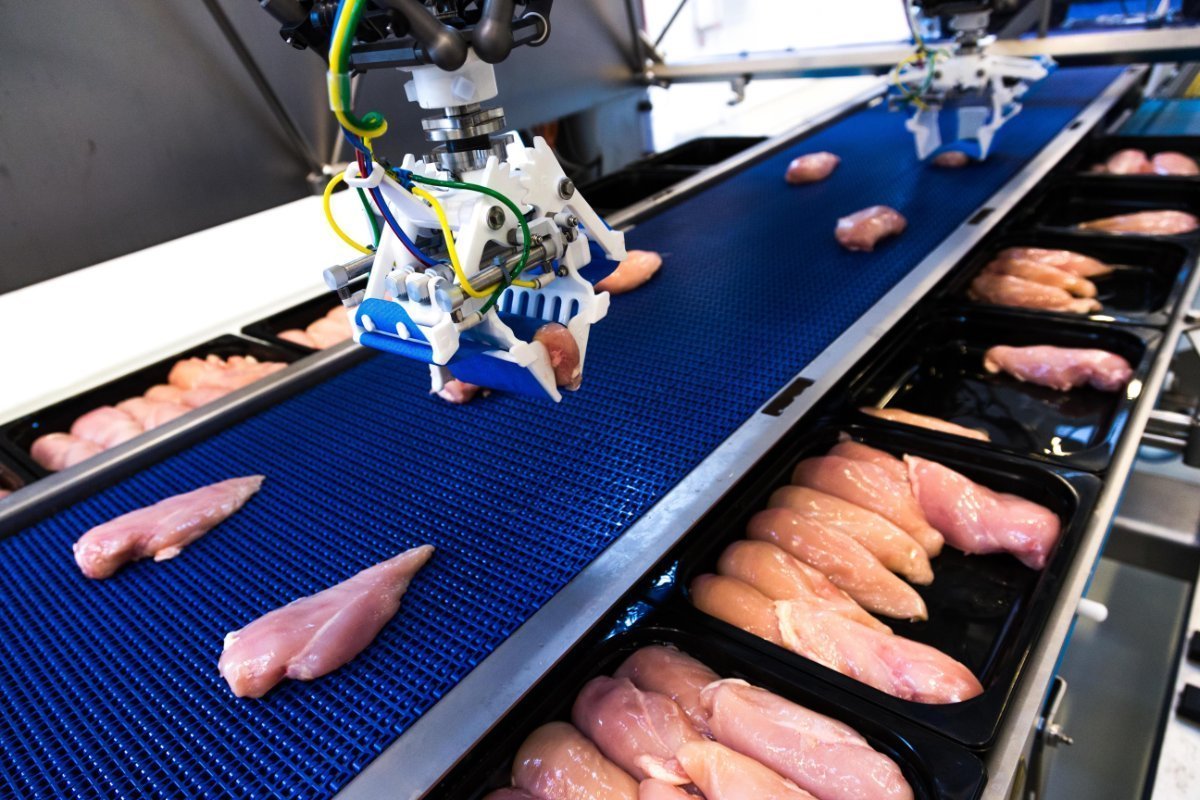

Agriculture and Food Processing – Nylon 6 stands up well to repetitive motion, cleaning chemicals, and wet conditions, especially when using food-safe grades. Examples:

- Conveyor rollers in packaging equipment.

- Cutting boards and food-processing machine parts.

Marine and Outdoor Equipment – With excellent corrosion resistance, Nylon 6 performs well in challenging outdoor environments. Examples:

- Dock rollers and boat pulleys.

- Non-corrosive fittings or fenders for marine use.

Robotics and Automation – Ideal for lightweight precision parts where noise reduction and smooth operation are essential. Examples:

- Quiet-running gear assemblies.

- Custom-machined robotic components.

Replacement for Metal Parts – Nylon 6 often substitutes for metal where weight savings, corrosion resistance, or reduced maintenance are priorities. Examples:

- Oil-filled bushings replacing greased metal versions.

- Lightweight wear strips reducing energy consumption.

Why Nylon 6 Excels in Demanding Environments

Whether replacing metal parts or improving efficiency in mechanical systems, Nylon 6 stands out for several key reasons:

Exceptional Mechanical Strength

Nylon 6 can withstand pulling, compressive forces, and impact without deforming. It resists repetitive stress and maintains integrity in high-friction applications, making it ideal for gears, bearings, wear pads, and machine parts.

Excellent Chemical Resistance

Nylon 6 is highly resistant to oils, greases, and many solvents, making it dependable in automotive, agricultural, and industrial settings. However, its resistance is limited and nylons can be attacked by strong acids.

Lower Weight, Quieter Operation

It weighs up to seven times less than steel, reducing load in assemblies and improving energy efficiency. Nylon parts also operate more quietly than metal equivalents—ideal for noise-sensitive environments.

Resistance to Corrosion

Unlike metal, Nylon 6 does not corrode - even in moist environments - extending the life of components and reducing maintenance needs.

Moisture Absorption and Stabilised Grades

Standard Nylon 6 can absorb moisture from the environment, which may affect dimensional stability in some applications. For this reason, stabilised grades like LFX Oilon Nylon are available. These grades are specially designed to minimise water uptake and maintain consistency over time.

LFX Oilon Nylon – Built-In Lubrication for Demanding Applications

LFX Oilon Nylon is a cast Nylon 6 that incorporates internal oil additives during production. This self-lubricating property results in:

- Lower friction

- Superior wear resistance

- Reduced maintenance in high-load, slow-moving applications

Ideal for pulleys, guides, bushings, and bearing surfaces, LFX Oilon Nylon is perfect for dry-running or hard-to-reach lubrication areas, such as heavy industrial machinery and automation systems.

Material Properties Comparison: Extruded vs Cast vs LFX Oilon Nylon

| Property | Extruded Nylon 6 (PA6E) | Cast Nylon 6 (PA6C) | LFX Oilon Nylon (Oil-Filled) |

|---|---|---|---|

| Molecular Weight | Lower – good general strength | Higher – stronger and denser | Higher – similar to cast, enhanced with internal lubricants |

| Tensile Strength | High – suitable for most parts | Very high – ideal for heavy-duty use | Very high – slightly reduced vs standard cast due to oil content |

| Dimensional Stability | Moderate – higher internal stresses | Excellent – minimal internal stress | Excellent – stable, plus reduced friction effects |

| Wear Resistance | Good – suited for moderate wear applications | Superior – ideal for high-friction, heavy-load parts | Outstanding – built-in oil significantly reduces wear |

| Impact Resistance | Good – can absorb moderate shocks | Very high – absorbs heavy impacts | Very high – similar to cast, with added smooth operation |

| Friction Level | Standard – requires external lubrication | Standard – requires external lubrication | Very low – self-lubricating, often no external lubrication needed |

| Operating Temperature (Continuous) | Up to 70°C | Up to 70°C | Up to 90°C |

| Chemical Resistance | Resistant to oils, greases, and many solvents. Many strong acids able to attack Nylon. | Similar to extruded | Similar, plus enhanced performance in dry-running conditions |

| Cost | Lower – most economical option | Slightly higher than extruded | Highest due to specialised additives |

| Available Sizes | Standard rods, sheets, and profiles | Can be produced in very large, custom sizes | Similar to cast, though may be slightly more limited |

| Typical Applications | Gears, spacers, bushings, wear strips | Large gear blanks, rollers, high-load bushings | Dry-running bushings, pulleys, guides, slow-moving high-load parts |

Disadvantages of Nylon 6

While Nylon 6 is an excellent engineering plastic thanks to its strength, wear resistance, and versatility, it isn't perfect for every application. Understanding its disadvantages will help you to decide when another material might be a better fit — or when a modified grade, like Nylon 6 LFX, is needed.

Here’s a detailed breakdown of the main disadvantages of Nylon 6:

-

Moisture Absorption: High water absorption is one of the biggest drawbacks of Nylon 6. It can absorb up to 8–9% (compared to just 0.2% for Perspex® Acrylic) of its weight in moisture at saturation, leading to dimensional changes, reduced mechanical strength, and an increased tendency to creep under sustained loads.

-

Poor UV Resistance: Prolonged exposure to sunlight can cause surface chalking, discoloration, and brittleness, reducing the material’s impact strength and overall lifespan.

-

Requires External Lubrication: Standard Nylon 6 is not self-lubricating and needs external lubrication for moving parts. Without it, friction can increase wear and shorten part life, especially in dry-running conditions.

-

Temperature Limitations: Nylon 6 loses strength and stiffness above its continuous use temperature (70°C for extruded, 70°C for cast, 90°C for LFX). Short-term peaks up to 150°C are possible but can lead to deformation if sustained.

-

Chemical Sensitivity: Nylon 6 is resistant to oils and many solvents but can be damaged by strong acids, alkalis, and some oxidising agents, which may cause swelling or degradation.

-

Creep Under Load: Under constant mechanical stress, especially in warm or humid environments, Nylon 6 can deform permanently over time, making it unsuitable for high-precision or continuously loaded parts.

Frequently asked questions

Both forms of Nylon 6 (cast and extruded) are not fully waterproof, they are hygroscopic, meaning they naturally absorb moisture from the environment. Whilst they don't dissolve or degrade in water, the absorbed moisture can affect their performance and dimensions, especially in precision applications. Nylon 6 can absorb 2-3% by weight at typical room humidity or as much as 8-9% by weight at full saturation.

The main difference lies in how the material is manufactured. Nylon 6 Cast is stronger, tougher and has better wear resistance, whereas Nylon 6 Extruded is softer, easier to machine and more flexible.

Nylon 6 is generally difficult to bond and would need special adhesives

Yes, nylon is a plastic — specifically, it’s a type of synthetic polymer belonging to the polyamide family. It was first developed in the 1930s and is one of the most widely used engineering plastics today.

Why Nylon is considered a Plastic

- Plastics are materials made of polymers — long chains of repeating molecules.

- Nylon is a man-made polymer produced through chemical polymerisation, making it a synthetic plastic.

- It’s classified as a thermoplastic, meaning it:

- Softens when heated.

- Hardens again when cooled.

- Can be melted, extruded, and remoulded into different shapes like rods, sheets, or fibres.

More specific information on Nylon can be found on our blog, see Why Engineers Rely on Nylon 6 for High-Load, High-Wear Applications

{{product.colours}} Colours

{{product.colours}} Colours